Seal as proof for authenticity, according to EU Directive 2011/62/EU

Starting in February 2019, all prescription medicines sold in the EU must have a seal that serves as proof of authenticity, among other safety features. This is a provision of EU Directive 2011/62/EU, which was adopted in 2011, supplemented by the delegated regulation (EU) 2016/161/EU. From the cost-benefit point of view, sealing labels are an especially interesting way to continue using folding boxes that are already in use. These safety labels permanently affix the tuck-in flap to the body of the box.

Flexible and pliable – for reliable application

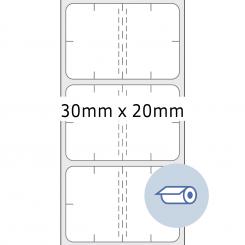

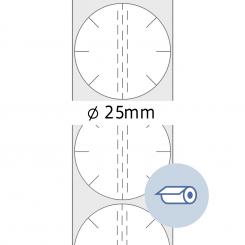

In terms of economic viability and technical practicality, conventional rectangular or round labels, preferably with additional security perforations, are the best solution. The label material, which is usually transparent PE or PP film, is especially flexible and pliable – ideal for labelling around corners. The adhesives are highly resistant to water, hot air and a variety of solvents. Only if these conditions are met is the label impossible to peel off, even from highly varnished cartons, without either being destroyed or visibly damaging the surface. For especially difficult surfaces, special adhesives are available, and the labels can additionally be provided with security perforations. One and the same sealing label variant can be used with an abundance of packaging materials and numerous different surfaces. The transparent, glossy material does not cover the information on the package or interfere with the brand image.

Designed for reliable processing: labellers plus labels from HERMA

Besides sealing labels, HERMA also offers labelling machinery that can be integrated into your packaging facilities for perfectly coordinated production. Attaching tamper-evident labels requires a high degree of precision. The labels, which are usually very small, must be stuck to the side of the tuck-in flap in such a way that they protrude by about half their length up and down beyond the body of the folding carton. A folding rail then “irons” the two unattached parts of the label through 90 degrees, and foam rollers press the labels against the pack so that the tuck-in flap is permanently affixed to the carton. The machine is equipped with sensors for checking the placement of the labels and rejecting any defective ones. Labels can also be given special characteristics, such as luminescence, to facilitate the inspection process.

Vour benefits with Tamper Evident labels:

- Sealing labels that efficiently comply with tamper-evident requirements

- Extremely strong adhesion and excellent flexibility – for labelling curved surfaces with small radii and labelling around corners

- Suitability for all common tuck-in flaps, no need to change the carton design

- Highly resistant adhesives for reliability

- Increased protection against tampering (for example, by means of security perforations)

- Proof of authenticity and provision of security (tamper-evident)

- Suitability for many different packaging materials and surfaces

- An integrated solution comprising tamper-evident labels plus a labelling machine with a modular design – perfectly coordinated high-speed production

Extra security – with HERMA tamper-evident labels

We manufacture both printed and unprinted sealing labels: quickly, reliably and on time. In the sizes you want, tailored to your pharmaceutical package. In top HERMA quality. Further information about our tamper-evident solutions can be found here:

Discover more about HERMA tamper-evident solutions

A HERMA system solution with labels and a labelling machine offers you an efficient way to meet tamper-evident requirements. Exploit our know-how and let us advise you. Our ‘Solutions’ section has many more examples of label usage for a wide range of industries and requirements.

Protection against the unauthorised opening of medicines with tamper-evident labels for counterfeit protection

Find out for yourself and benefit from the expertise of HERMA’s application engineers. Use the contact form to let us know what you need. We’ll give you individual advice to help you find materials that are suited to your specific applications.

Please use this contact form for inquiries about industrial requirements.

If you have any questions about HERMA branded products in smaller packaging units, we look forward to your inquiry using the contact form "Office and Home".

Would you like to learn more about our sealing labels?

In addition to special tamper-evident labels HERMA offers sealing solutions for a wide range of requirements, for example packaging of foodstuffs:

- Resealing of packaging

HERMA sealing labels allow easy resealing of packages that have been opened. No damage is done to the packaging. The product is kept fresh and is ideally protected – your customers will appreciate this because they will not need any other kind of seal. Another advantage is that the labels can be resealed even when the package surface is uneven. Sealing labels are manufactured from film, sometimes with partial adhesion. Special stamping and gripping tabs ensure easy use. Whether you need printed or unprinted labels, HERMA can produce them on rolls to your specifications. They can be applied to film, cardboard, paper or plastic. - Tamper resistance and proof of authenticity

There are many names for labels of this kind: security labels, anti-tamper labels, tamper-evident labels, anti-counterfeiting labels. What they all have in common is a focus on tamper protection and product authentication. HERMA sealing and Tamper Evident labels show users that products have not been opened or tampered with. They can be applied to all kinds of surfaces: film, cardboard, paper, plastic or metal. HERMA offers a wide range of high-security solutions. Our specialists will produce sealing labels for you made of special composites (tamper-evident, void) and with security perforations. Also for extreme conditions. With extremely strong adhesives. On rolls, printed or unprinted. - Versatility

Our sealing labels can be applied to packaging made of film, paper, plastic, metal or glass, ensuring secure closure even when used on corners on uneven surfaces. They can even hold cardboard boxes together. Find out for yourself and benefit from the expertise of HERMA’s application engineers.. - Other applications

HERMA sealing labels can also be used as promotional labels, for example to convey advertising messages. Get the most out of our sealing labels by adding product information, best-before dates, batch numbers or instructions on use.

Discover our strengths and your advantages:

HERMA - your label manufacturer

![[Translate to English:] Mit Sicherheitseffekt](/fileadmin/News/Industrieetiketten/Tamperevident-HERMAsuperPerm-2.jpg)